HOW IT WORKS

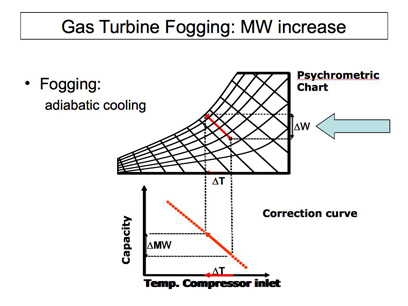

Adiabatic cooling

Water is injected through special atomizing nozzles producing a fog of very fine droplets which evaporate almost instantaneously. The evaporation process results in a cooling effect on the inlet air feeding the compressor. The air can nominally be cooled to the corresponding wet bulb temperature.

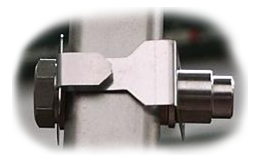

Nozzle and optimum droplet size

The EnergyFog world wide patented system design includes a nozzle producing optimum droplet size at an operating pressure of 70 - 140 bar. This lower atomizing pressure in comparison with the market standard, results in

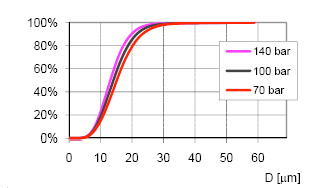

The graph shows the cumulative percentage of droplets of a given diameter (0-60 microns) produced at different nozzle pressures. More than 90% of the droplets produced by the nozzle measure less than 20 microns over a pressure range of 70 to 140 bars. Absence of large droplets is key to efficient cooling and minimum water usage.

EnergyFog's nozzle produces a Sauter mean drop diameter D32 of 14 microns or less, ideal for complete evaporation and effective cooling.

EnergyFog Systems has long term and ongoing research and development programmes and nozzle performance certification in cooperation with CNR - Politecnico Milano.

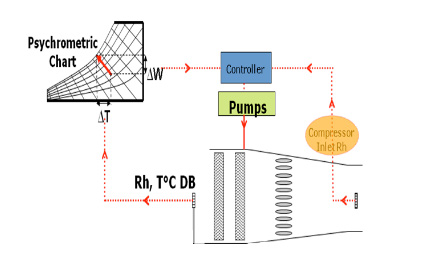

Stage predictive control: Beyond simple humidity control

Most fogging systems operate through a predictive control loop which estimates, from ambient conditions, the quantity of water to be injected in the air inlet to reach water saturation and then sets this level with no feedback from the results. EnergyFog's proprietary control system allows reliable direct measurement and control of the actual relative humidity of the air at the compressor inlet, and feeds this signal back to the controller, which compares it to the predictive result. This system allows detailed and optimum control of the fogging rate, ensuring automatic detection and correction in the event of excessive fogging. Because other fogging systems use multiple fixed-volume pumps which operate in a finite number of stages, they will usually fall short of optimum saturation. EnergyFog variable speed control pumps allow fine control of the water quantity injected and most effective cooling.